Nickel-Metal Hydride (Ni-MH) batteries have been a reliable source of rechargeable power for over two decades. Known for their balance of safety, cost, and moderate performance, Ni-MH batteries are widely used in consumer electronics, power tools, electric vehicles (EVs), and more. I will take you through an in-depth explanation of Ni-MH batteries, including their specifications, charging/discharging characteristics, design principles, and safety features.

What Are Ni-MH Batteries?

Ni-MH batteries are a type of rechargeable battery that uses a nickel oxide hydroxide cathode and a hydrogen-absorbing alloy anode. Compared to older Nickel-Cadmium (Ni-Cd) batteries, Ni-MH batteries are safer and environmentally friendly, as they do not contain toxic cadmium. These batteries are especially popular in applications that require a balance of energy density, cost-effectiveness, and safety.

The nominal voltage of a typical Ni-MH cell is 1.2V, and they can be configured in various sizes and capacities. They offer moderate energy densities of approximately 60-120 Wh/kg and are known for their excellent ability to handle deep discharges, making them ideal for applications where long life and consistent performance are essential.

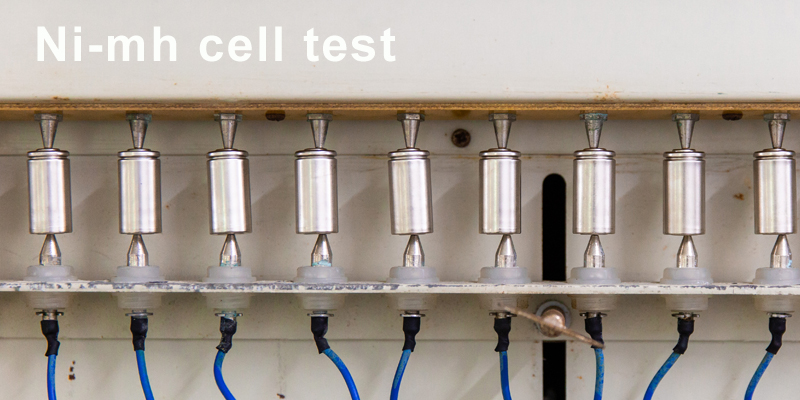

Ni-MH Battery Cell Specifications and Types

1. Cell Sizes and Voltage

Ni-MH batteries come in a wide variety of sizes, with each one suited to specific applications. The most commonly used sizes are:

- AA (1.2V nominal): 1,200 mAh to 2,500 mAh. Common in consumer electronics like remote controls, digital cameras, and flashlights.

- AAA (1.2V nominal): 600 mAh to 1,200 mAh. Used in devices with lower power consumption like small electronics and toys.

- C (1.2V nominal): 2,000 mAh to 5,000 mAh. Found in toys, camping lanterns, and other mid-power devices.

- D (1.2V nominal): 6,000 mAh to 10,000 mAh. Typically used in high-drain applications like large flashlights or emergency lighting systems.

- Industrial Cells: Larger cells with 1.2V to 12V nominal voltage, often used in hybrid electric vehicles, backup power systems, and power tools.

2. Energy Density

Ni-MH batteries offer an energy density ranging from 60 Wh/kg to 120 Wh/kg. While this is lower than that of lithium-ion batteries (which typically have energy densities of 250-300 Wh/kg), Ni-MH batteries still provide a reliable and affordable solution for many applications.

Charging and Discharging of Ni-MH Batteries

1. Charging Process

Ni-MH batteries have specific charging requirements to ensure maximum efficiency and lifespan. These batteries are generally charged at a nominal voltage of 1.2V per cell.

- Charging Voltage: The charging voltage for Ni-MH cells typically ranges between 1.4V to 1.45V per cell. This is the voltage at which the battery reaches full charge.

- Charging Current: Charging is usually done at 0.1C to 0.5C (where C refers to the battery’s capacity). For example, a 2,000 mAh cell can be charged at a rate of 200 mA to 1,000 mA.

- Temperature Range: Ni-MH batteries should be charged within the temperature range of 0°C to 45°C. Charging outside of this range can affect performance and lifespan.

2. Discharge Characteristics

When discharging, Ni-MH batteries exhibit different behaviors compared to other types of rechargeable batteries.

- Nominal Voltage During Discharge: Ni-MH cells maintain a steady 1.2V for much of the discharge cycle, making them ideal for devices that need consistent performance over time.

- Cut-off Voltage: The cut-off voltage for Ni-MH batteries is typically 1.0V per cell. Discharging below this voltage can cause permanent damage to the battery.

- Discharge Rate: Ni-MH batteries can safely discharge at rates of up to 1C (meaning the current equals the battery’s capacity). High-drain applications, such as power tools, can discharge at 5C or 10C, but this reduces the overall lifespan of the battery.

Applications of Ni-MH Batteries

1. Consumer Electronics

Ni-MH batteries are commonly used in AA and AAA sizes, providing a reliable power source for everyday electronics such as:

- Digital Cameras

- Flashlights

- Toys and Games

These batteries are often chosen for their balance of safety and cost-effectiveness.

2. Electric Vehicles and Hybrid Vehicles

Ni-MH batteries are used in hybrid electric vehicles (HEVs), such as the Toyota Prius, to store energy from regenerative braking systems and power the electric motor. A typical Ni-MH battery pack in an HEV may have voltages ranging from 6V to 300V, depending on the configuration.

3. Industrial Applications

Larger Ni-MH batteries are used in power tools, backup power systems, and other industrial applications. These batteries typically operate at 6V, 12V, or higher voltages and provide consistent performance under varying loads.

4. Medical Devices

Ni-MH batteries are widely used in medical devices like hearing aids, infusion pumps, and portable monitoring systems. The voltage for these devices typically ranges from 3.6V to 12V, depending on the application.

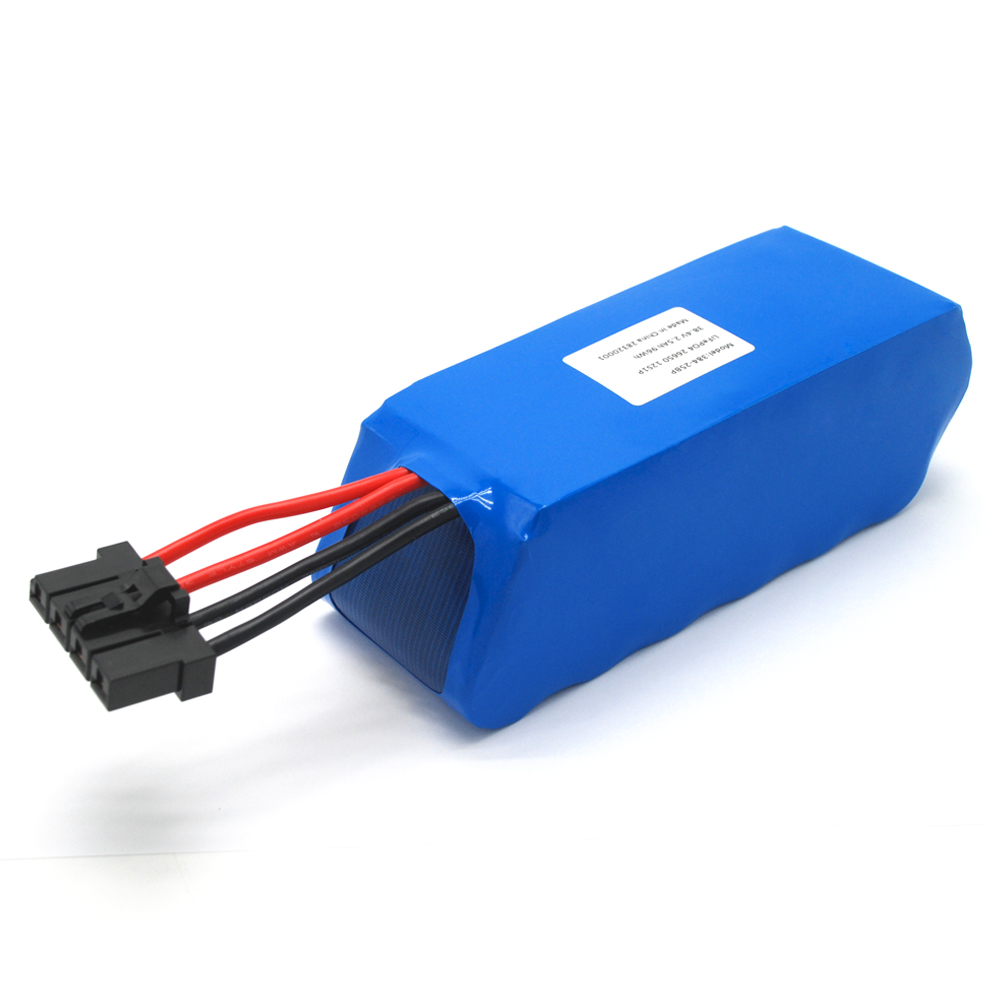

Designing Ni-MH Battery Packs

1. Series and Parallel Configurations

Ni-MH battery packs can be designed in both series and parallel configurations to meet the voltage and capacity requirements of different devices:

- Series Configuration: Increases the total voltage of the pack. For example, connecting 10 Ni-MH cells in series results in a 12V battery pack.

- Parallel Configuration: Increases the total capacity of the battery pack. For example, connecting four 2,000 mAh cells in parallel would result in a 2,000 mAh, 1.2V pack, while connecting ten cells would yield a 10,000 mAh pack.

2. Battery Management System (BMS)

While Ni-MH batteries are generally safer than lithium-based chemistries, a Battery Management System (BMS) is still recommended for large battery packs. The BMS helps ensure:

- Cell Balancing: Ensures that all cells within the pack charge and discharge evenly.

- Overcharge/Overdischarge Protection: Prevents damage by ensuring that no cell is overcharged or overdischarged.

- Temperature Control: Prevents overheating by monitoring and controlling the temperature of the battery pack.

Safety and Reliability of Ni-MH Batteries

1. Built-in Safety Features

Ni-MH batteries have several built-in safety features that make them safer compared to older battery technologies:

- Water-based Electrolyte: Unlike older Ni-Cd batteries, Ni-MH batteries use a water-based electrolyte, reducing the risk of leakage and combustion.

- Lower Internal Resistance: Ni-MH batteries have lower internal resistance, which helps them handle higher currents safely.

- No Toxic Heavy Metals: Ni-MH batteries do not contain toxic cadmium, making them more environmentally friendly than Ni-Cd batteries.

2. Preventing Overcharging and Deep Discharging

Ni-MH batteries should always be charged using a regulated charger that stops charging once the battery reaches its full capacity (1.45V per cell). Additionally, deep discharges (below 1.0V per cell) should be avoided to prolong the battery’s life.

Conclusion

Ni-MH batteries offer a reliable, safe, and cost-effective solution for a wide range of applications. Their moderate energy density, long cycle life, and safety features make them a great option for consumer electronics, industrial tools, electric vehicles, and medical devices. By understanding the specifications, charging/discharging characteristics, and safety features of Ni-MH batteries, you can make informed decisions when selecting the right power source for your needs.