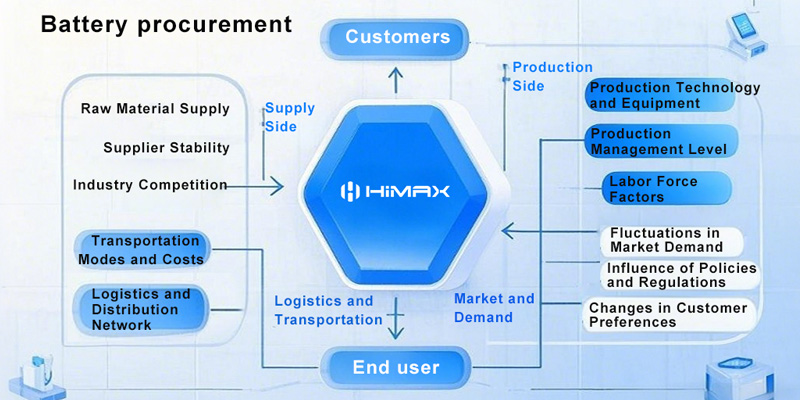

Introduction: Common Supply Chain Issues in the Battery Industry

The battery industry, like many others, faces numerous supply chain challenges that can affect procurement, delivery schedules, and overall costs. These challenges are often compounded by the volatility of raw material prices, logistics hurdles, and production delays. Understanding these issues and how to navigate them is crucial for businesses that rely on bulk battery purchases. This blog will explore the common supply chain challenges faced by the battery industry and offer strategies to mitigate them, ensuring that your procurement process remains efficient and reliable.

Challenge 1: Raw Material Volatility – How to Address Price Fluctuations and Supply Instability

One of the most significant challenges in the battery industry is the volatility of raw material prices, especially for key components like lithium, cobalt, and nickel. These materials are critical for the production of lithium-ion and LiFePO4 batteries, and their prices can fluctuate due to supply shortages, geopolitical factors, or demand spikes from industries like electric vehicles (EVs).

How to address this challenge:

- Long-Term Contracts: Establishing long-term contracts with suppliers can help lock in favorable prices and secure a consistent supply of raw materials.

- Diversifying Suppliers: Relying on a network of diverse suppliers from different regions can mitigate the risks associated with supply disruptions.

- Sourcing Alternatives: Exploring alternative materials or more sustainable sources, such as recycled materials, can help stabilize costs in the long run.

Challenge 2: Transportation Issues – Managing Delays and Optimizing Logistics

Transporting batteries, particularly large orders, comes with its own set of challenges, from delays in shipping to customs issues and freight shortages. These issues can cause delays, impacting customer satisfaction and potentially increasing costs.

How to address this challenge:

- Localized Warehousing: Setting up local warehouses or distribution centers can help ensure that products are readily available when needed, reducing shipping times and transportation costs.

- Optimizing Supply Routes: By collaborating with experienced logistics partners, businesses can identify the most efficient shipping routes and avoid common bottlenecks.

- Streamlining Customs Processes: Ensuring that all customs documentation and regulatory requirements are in order ahead of time can minimize delays and prevent costly fines.

Challenge 3: Production Delays – Navigating Long Lead Times and Quality Control Issues

Battery production often involves long lead times, especially for custom or large-volume orders. In addition, maintaining consistent product quality across multiple batches can be challenging, and production delays can push back delivery dates, affecting project timelines.

How to address this challenge:

- Forecasting Demand Accurately: By accurately forecasting demand and placing orders well in advance, businesses can ensure that production schedules are aligned with procurement needs.

- Ensuring Quality Control: Working with suppliers that have robust quality assurance processes in place ensures that products meet specifications, reducing the risk of defects or delays due to rework.

- Building in Buffer Time: Including buffer time in production schedules allows for unexpected delays or quality issues to be addressed without affecting the final delivery date.

Cooperation Strategy: Partnering with Suppliers with Strong Supply Chain Management

To overcome these supply chain challenges, it’s crucial to partner with a supplier that has proven experience in managing complex supply chains. Suppliers with strong logistical capabilities, established relationships with raw material providers, and efficient production processes are better equipped to handle the pressures of bulk procurement. By building a long-term relationship with such a supplier, you can ensure that your battery procurement process remains smooth and predictable, even during times of supply chain instability.

Himax’s Solutions: Managing Supply Chain Challenges with Precision

At Himax Battery, we understand the challenges that our customers face in navigating the complexities of the battery supply chain. We employ a range of strategies to address these issues and ensure timely delivery of high-quality products:

- Efficient Supply Chain Management: Through careful planning and relationships with reliable suppliers, we mitigate risks related to raw material volatility and production delays.

- Local Warehousing and Fast Delivery: With our warehouse facilities in strategic locations, including Australia, we ensure fast and reliable delivery times for bulk orders.

- Quality Assurance and Flexibility: We maintain rigorous quality control throughout production, and our flexible approach allows us to adapt quickly to changing customer demands or supply chain disruptions.

By working with Himax, customers benefit from our well-established supply chain expertise and commitment to delivering custom battery solutions on time, every time.

Conclusion: Overcoming Supply Chain Challenges with the Right Supplier

Navigating the complexities of the battery supply chain can be daunting, but by choosing the right supplier, businesses can mitigate common challenges such as raw material volatility, transportation issues, and production delays. A reliable supplier with a strong track record in supply chain management will help ensure that your bulk battery procurement runs smoothly and efficiently, even during times of uncertainty.

Partnering with a supplier like Himax, which excels in managing these challenges, can provide the stability and reliability you need to keep your projects on track and your operations running without interruption.