In the world of power solutions, custom battery design holds a pivotal position, especially for customers with bulk purchase needs. Selecting a transparent and efficient design process is crucial, as it directly impacts the performance and cost – effectiveness of the end – products.

Requirement Assessment Stage

The journey of custom battery design begins with in – depth communication with the customers. We engage in detailed discussions to accurately understand their battery requirements. This involves determining performance standards such as energy density, discharge rate, and cycle life. Technical parameters like voltage, capacity, and physical dimensions are also carefully defined. By working closely with the customers, we ensure that every aspect of their needs is taken into account, laying a solid foundation for the subsequent design work.

Sample Design and Testing

Once the requirements are clear, the prototype design phase commences. Our experienced design team uses advanced software and tools to create initial prototypes that meet the specified parameters. These prototypes are then transformed into actual samples for verification. Rigorous testing procedures are carried out, including performance testing under various conditions, safety testing, and durability testing. This ensures that the batteries not only meet but also exceed the customer’s performance expectations before moving forward to the mass – production stage.

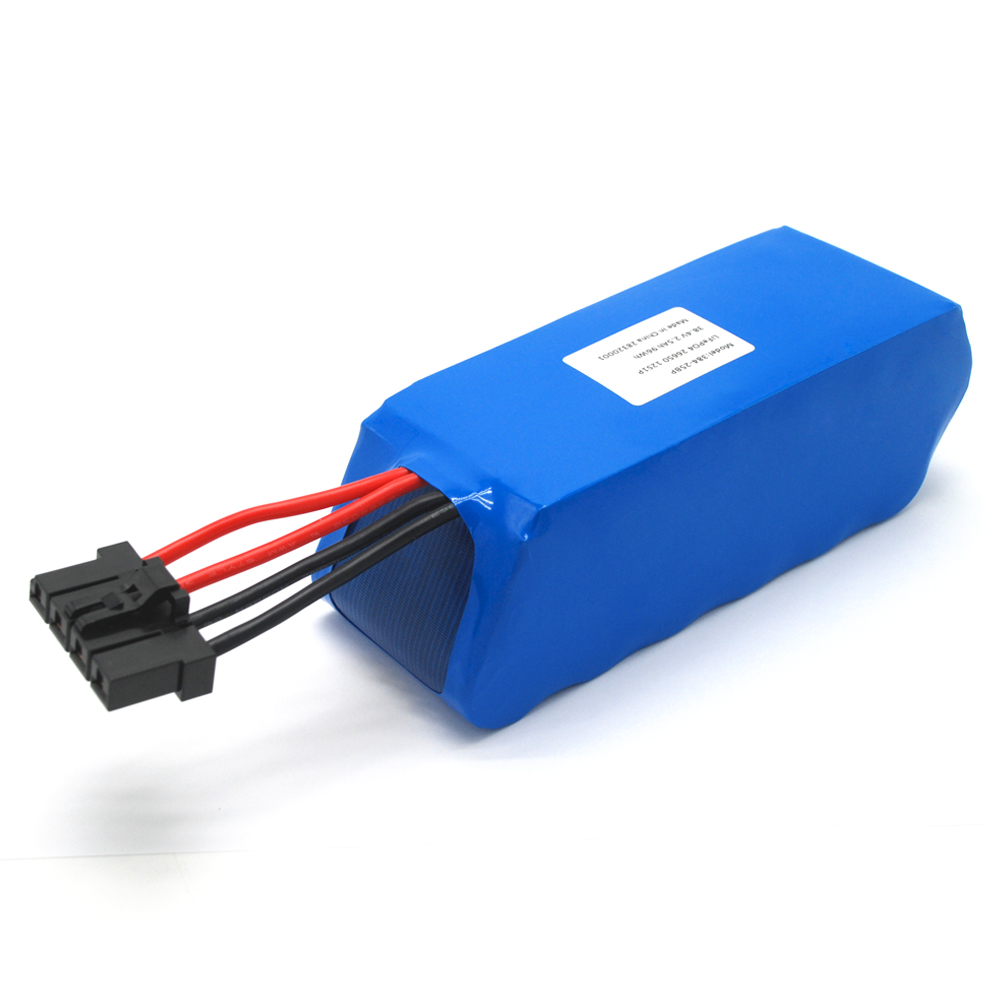

Mass Production and Delivery

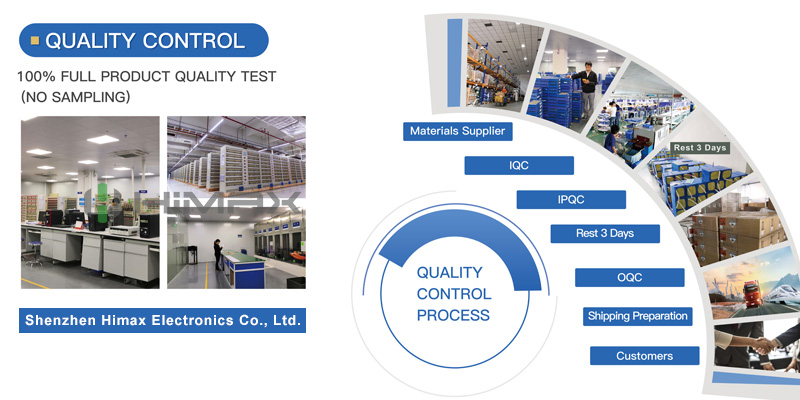

When the samples are approved, we enter the mass – production phase. Our state – of – the – art production facilities are equipped to handle large – scale manufacturing efficiently. Stringent quality control measures are implemented throughout the production process. Each battery cell and the final assembled battery pack undergo multiple inspections to guarantee consistent quality. Before delivery, a final comprehensive check is carried out to ensure that the products are in perfect condition and ready to be shipped to the customers.

Himax’s Custom Design Process

Himax has rich experience in custom battery design. We provide all – round support to our customers. From the initial requirement assessment, our technical experts offer professional advice and solutions. During the sample design and testing, we collaborate closely with the customers, making timely adjustments according to their feedback. In the mass – production stage, our advanced production management system ensures high – quality output and on – time delivery. This comprehensive approach has enabled us to ensure the high – quality delivery of custom batteries time and time again.

Conclusion

The custom battery design and delivery process is a complex yet well – organized journey. From accurately assessing customer requirements to delivering high – quality products, every step is crucial. For bulk – purchasing customers, choosing a reliable partner like Himax can make a significant difference. We invite you to partner with us for all your custom battery needs and experience the benefits of our professional and efficient design and delivery services. Let’s work together to power your future projects.